Discover the Benefits of Making Use Of CNC Machining Solutions for Precision Engineering and Manufacturing

CNC machining solutions use significant advantages for precision design and manufacturing. By using advanced computer-controlled equipment, these solutions guarantee high degrees of precision and effectiveness. This modern technology permits the creation of complex components from various materials, minimizing human error and production time. The advantages expand past precision alone, hinting at much deeper impacts on performance and cost-efficiency that are necessary for contemporary sectors. Discovering these facets reveals an extra considerable understanding of CNC machining's duty.

Improved Precision and Accuracy

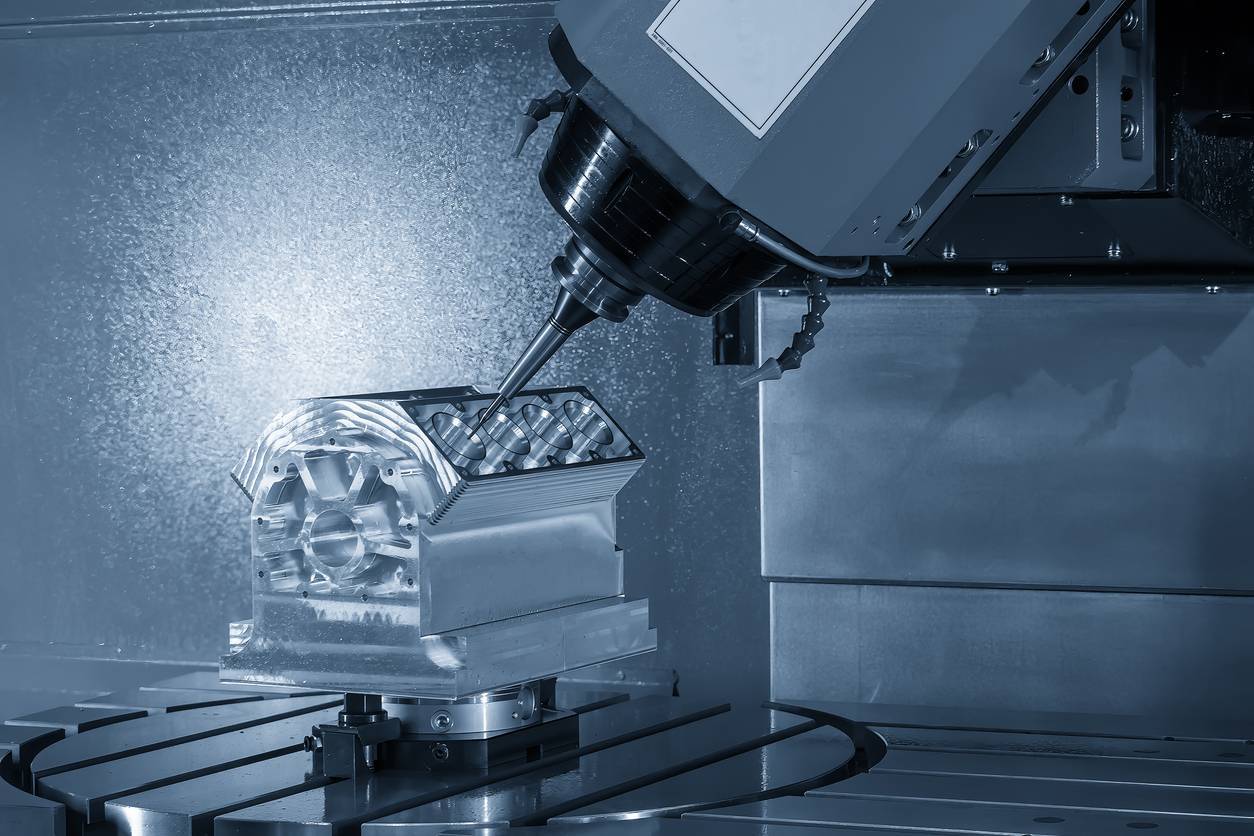

As markets increasingly require higher requirements, CNC machining solutions have actually become an essential service for attaining enhanced precision and accuracy in design applications. These services use sophisticated computer-controlled equipment to create intricate parts that meet rigid requirements. The capacity to program specific dimensions decreases human mistake, making certain that each part is made to exacting tolerances.

CNC machining is particularly helpful in fields such as aerospace, automotive, and clinical devices, where accuracy is vital. The technology permits for the development of complicated geometries that conventional machining methods may battle to attain. By using CAD designs, CNC makers can reproduce styles with impressive fidelity, resulting in consistent top quality throughout production runs.

Increased Effectiveness and Performance

CNC modern technology enables for the synchronised handling of several parts, leading to greater manufacturing prices. The ability to run machines continuously, even throughout non-working hours, maximizes operational time and resource usage. Furthermore, the quick setup and changeover times related to CNC machining help with rapid adjustment to different task demands, making it possible for makers to respond quickly to market demands.

Economical Manufacturing Solutions

CNC machining permits for fast prototyping and production runs, which assists to streamline the production process and lower lead times. The ability to create complicated geometries with very little material waste better adds to cost savings. tool and die maker. As an outcome, business can allocate funds more effectively and buy various other locations of their operations. Overall, CNC machining solutions offer a reliable pathway for services to enhance earnings while keeping high standards in product high quality and performance

Adaptability in Product Compatibility

The adaptability of CNC machining services in product compatibility is among its most considerable benefits. This capability permits manufacturers to collaborate with a varied series of products, consisting of compounds, plastics, and metals. Each product can be finely machined to meet specific engineering needs, causing parts that are both premium and useful. For light weight aluminum, instance and steel are typically utilized for their stamina and sturdiness, while plastics can be picked for their corrosion-resistant and light-weight residential or commercial properties. CNC equipments are outfitted to manage different product properties, guaranteeing that the wanted specs are met precision. This flexibility not just enhances navigate to these guys the design possibilities but likewise enables makers to tailor their products to numerous industry demands, from aerospace to clinical and automobile applications. Eventually, the capacity to efficiently make use of several products streamlines the manufacturing procedure and broadens the extent of innovative design services.

Streamlined Prototyping and Style Version

Improving the prototyping and design version process is a crucial advantage of advanced machining technologies. CNC machining solutions permit designers and developers to swiftly create precise prototypes, promoting fast screening and examination. This efficiency greatly minimizes the moment from principle to manufacturing, allowing business to repeat layouts quickly based upon real-world comments.

Additionally, CNC machining's high accuracy decreases errors, making sure that each model closely mirrors the end product specs. The ability to collaborate with various products better improves the design opportunities, permitting complete testing across various situations.

Consequently, businesses can fine-tune their items better, adjusting to market demands and consumer choices. This responsiveness is crucial in today's affordable landscape, where technology and rate are vital. Using CNC machining services not only speeds up the growth procedure yet additionally boosts the total top quality and dependability of the final made products.

Regularly Asked Concerns

What Industries Advantage Most From CNC Machining Providers?

The aerospace, vehicle, medical, and electronic devices industries benefit most from CNC machining services. These markets call for high precision, complex designs, and consistent quality, making CNC machining necessary for generating intricate parts and conference stringent market criteria.

Exactly How Does CNC Machining Compare to Standard Production Methods?

CNC machining uses better accuracy, versatility, and performance compared to standard production methods. It lessens human mistake, makes it possible for complex designs, and enables quick prototyping, ultimately causing enhanced production top quality and reduced preparations.

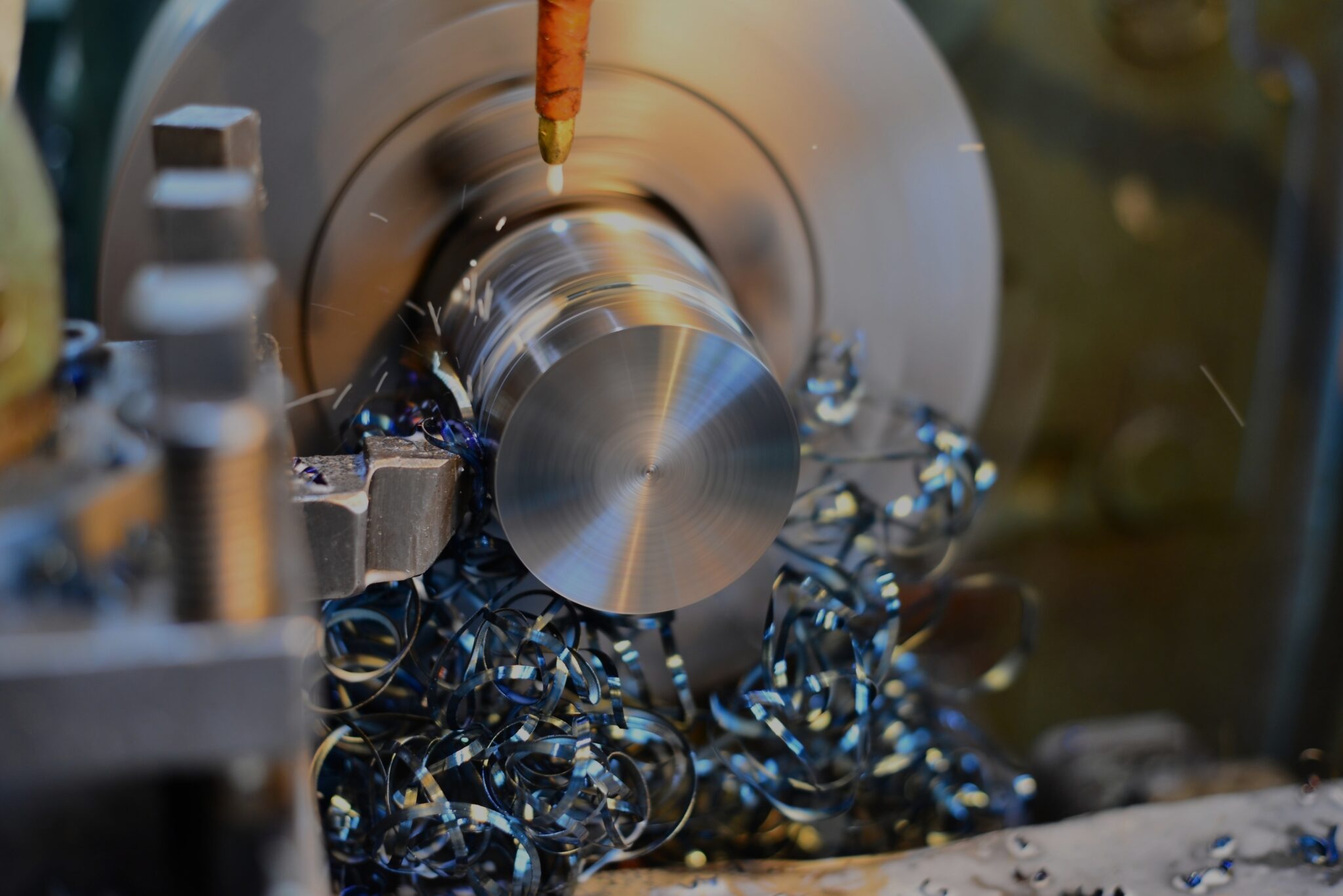

What Kinds Of CNC Machines Are Frequently Used?

What Is the Regular Lead Time for CNC Machining Projects?

The regular preparation for CNC machining jobs normally varies from a few days to several weeks, depending on factors like intricacy, product availability, task size, and the producer's work, affecting overall delivery timelines.

Exist Any Type Of Limitations to CNC Machining Solutions?

CNC machining solutions do have constraints, including product restrictions, complexity of designs, and size limitations. Additionally, detailed geometries may need specific tooling, which can raise manufacturing time and costs, see this impacting total project usefulness.

CNC machining solutions offer substantial advantages for accuracy design and production - fast prototyping. As markets significantly demand greater criteria, CNC machining services have arised as a vital option for achieving boosted accuracy and precision in engineering applications. CNC machining services not only improve precision but likewise considerably official website boost performance and productivity in manufacturing processes. CNC machining supplies better accuracy, flexibility, and performance contrasted to standard production approaches. Frequently made use of CNC devices include CNC turrets, CNC milling equipments, CNC routers, CNC plasma cutters, and CNC laser cutters